摩擦垫片在摩擦握把关节中的应用The use of friction shims in friction grip joints

**摩擦垫片在摩擦握把关节中的应用**

**2025年5月1日**

在《紧固件与固定》杂志的一月至二月刊中,Bolt Science Ltd公司的Bill Eccles博士讨论了界面摩擦在摩擦握把关节中的重要性。在这篇后续文章中,他强调,拥有一种经过验证的方法来增加界面摩擦力非常有用,它可以作为解决使用中问题或在承受剪切载荷应用中最小化所需螺栓尺寸的一种途径。

一些经过验证的方法包括:使用钻石浸渍摩擦垫片、使用具有工程化表面的摩擦垫片,或在板材表面使用热喷涂涂层。增加承受剪切载荷接头中静摩擦系数的一个优点是,可以实现更大的设计安全裕度,或者允许使用更小的螺栓。

**摩擦垫片在摩擦握把接头中的应用**

摩擦垫片,也称为防滑垫片,是插入接头两个表面之间的薄金属或复合材料,用以增加摩擦力和提高抓握力。它们能增加其所在的两个表面之间的静摩擦系数,减少在负载下表面相互滑动的趋势。

摩擦垫片通常通过表面粗糙度和材料特性的结合来增加表面之间的摩擦力。通常,摩擦垫片由不锈钢、钛或特殊涂层复合材料等材料制成。垫片的表面通常带有纹理或涂有摩擦增强材料,以最大限度地提高抓握力。

当对接头施加负载时,在施加剪切载荷时,摩擦垫片能为接头滑动提供额外的阻力。通过在接头中放置摩擦垫片,已解决了疲劳和螺栓松动问题。螺栓弯曲疲劳失效通常是接头滑动和自身松动导致的结果。

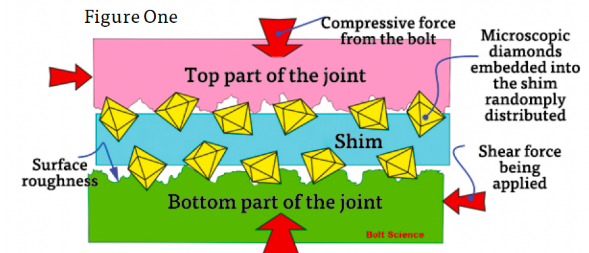

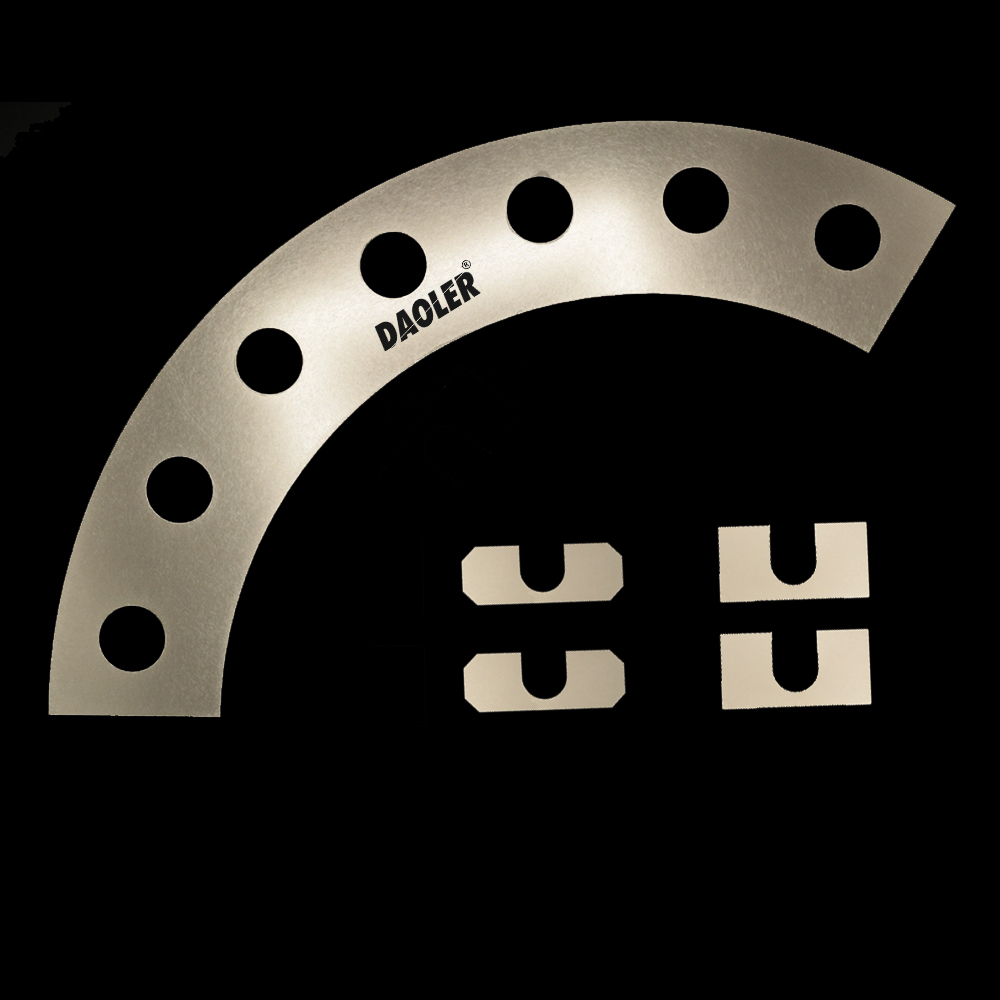

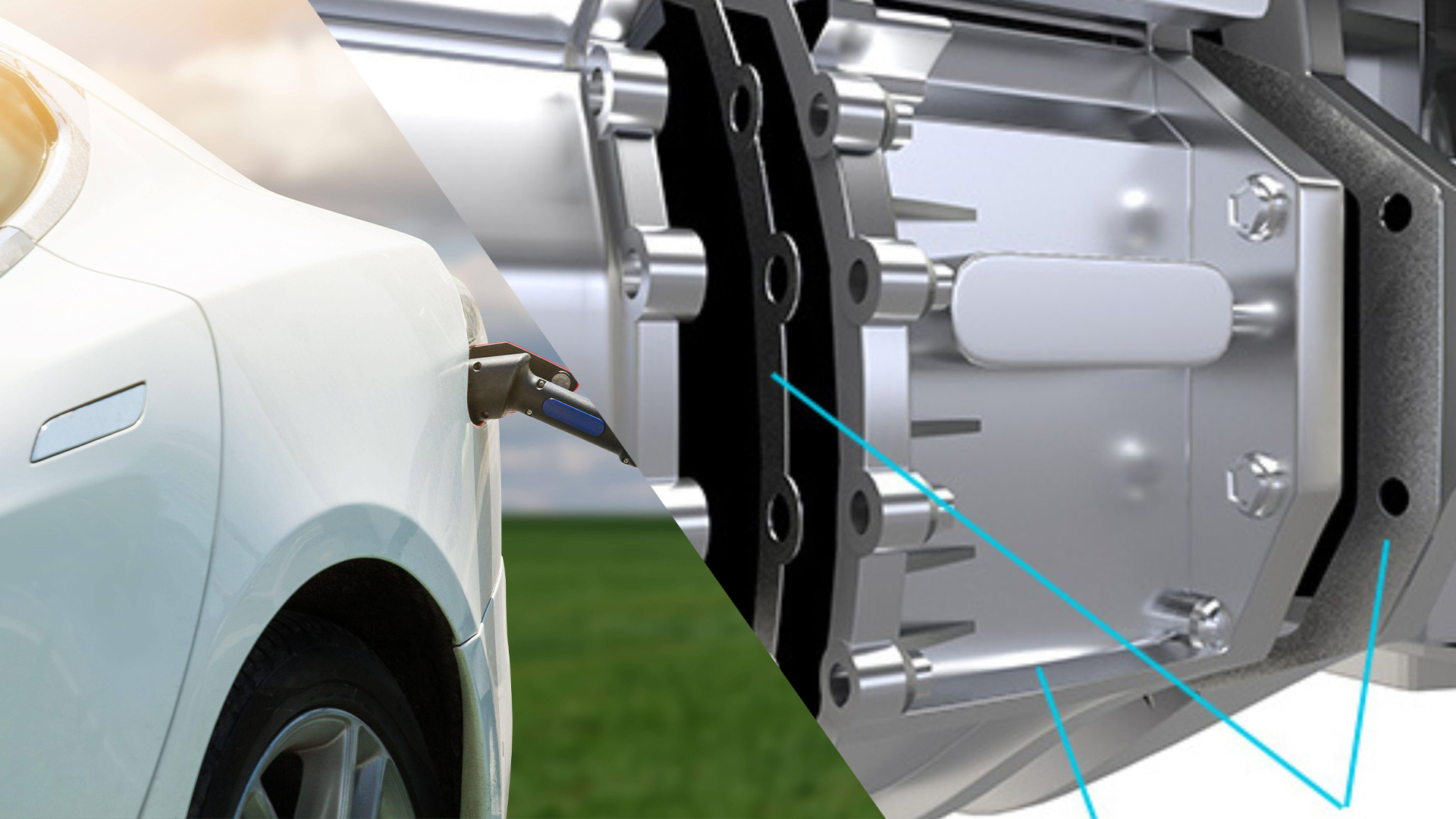

钻石涂层垫片可从多家供应商处获得,最著名的是3M和ATELA。这些垫片由带有化学镀镍涂层的薄钢板组成,其中嵌入了微观钻石——钻石的尺寸小到肉眼不可见。如上方图一所示,垫片被放置在剪切平面上的接头界面处,以便在施加螺栓拧紧产生的夹紧力时,钻石能咬入两个表面。

根据3M在2024年9月的一份新闻稿,该公司已在全球售出超过3亿片摩擦垫片。此类垫片提供的静摩擦系数取决于金刚石粒度、接触压力以及所涉及的材料配对。基于3M网站上的信息,使用此类垫片时静摩擦系数通常在0.7左右,但会根据材料、金刚石粒度和表面粗糙度而变化。

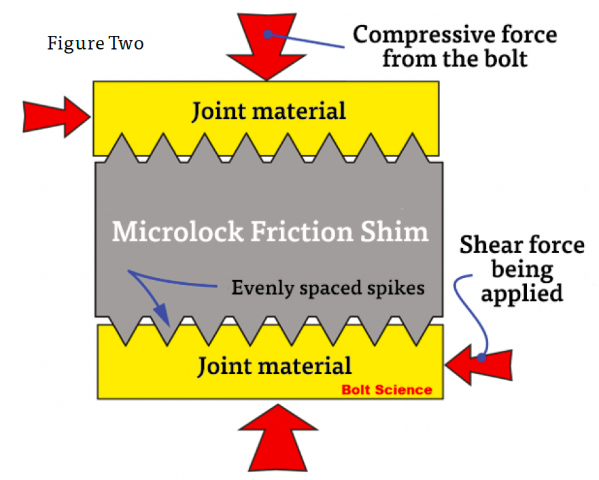

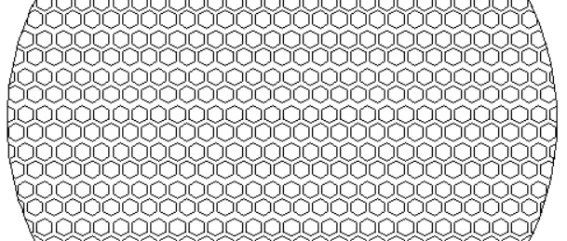

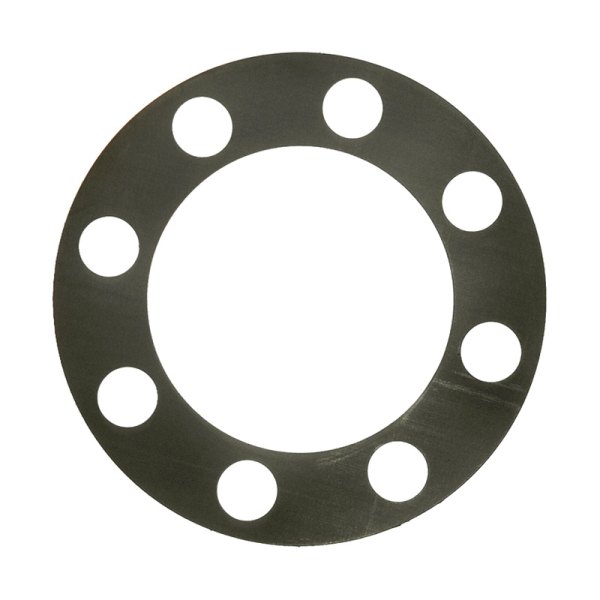

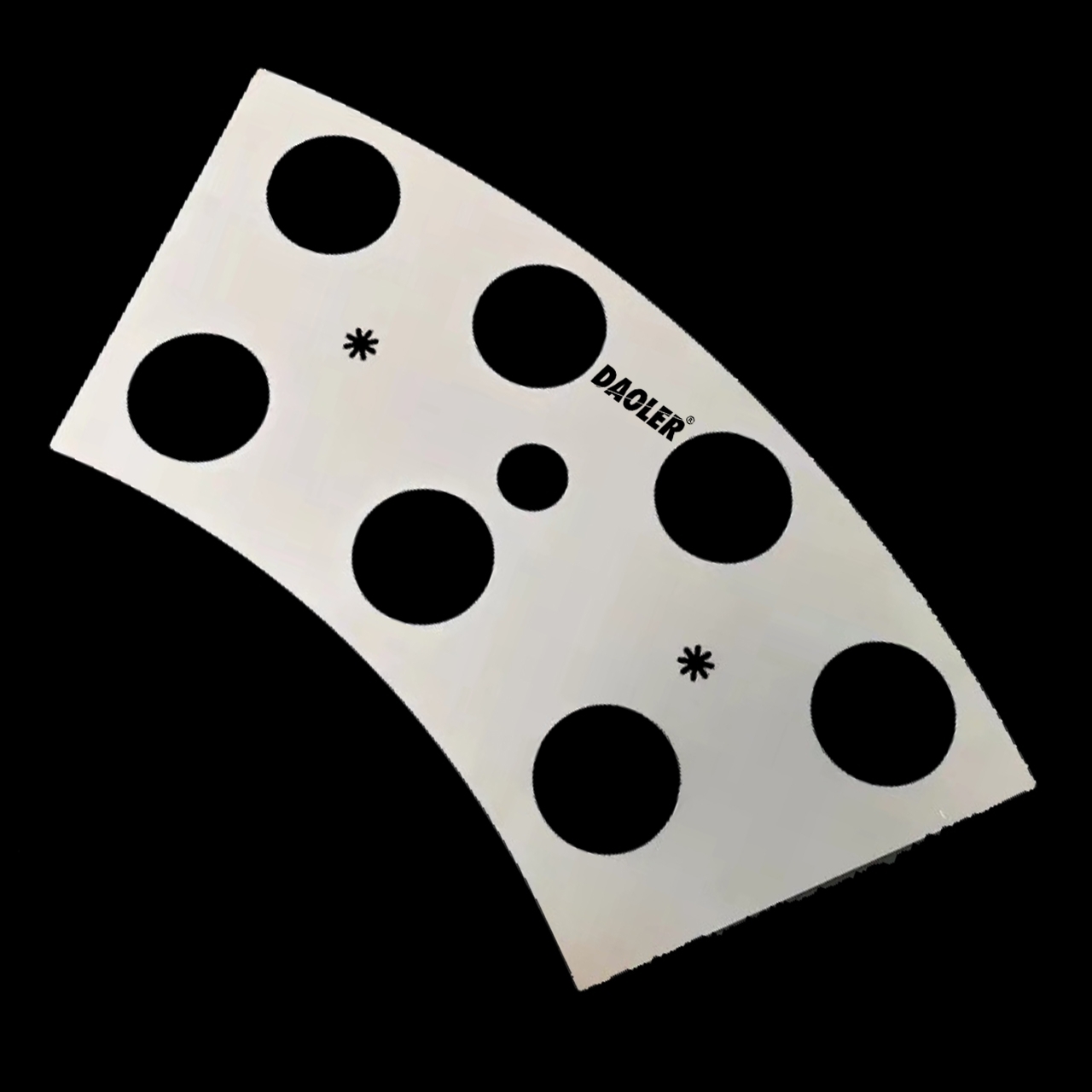

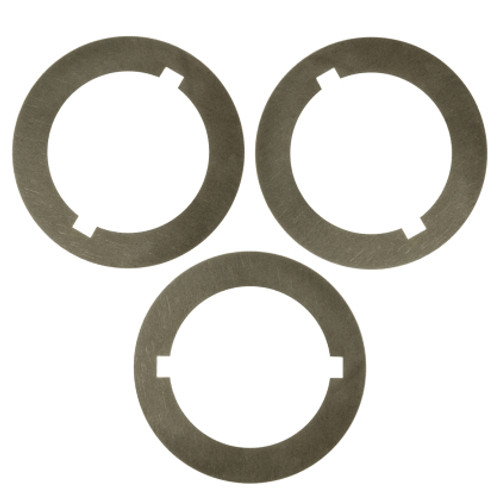

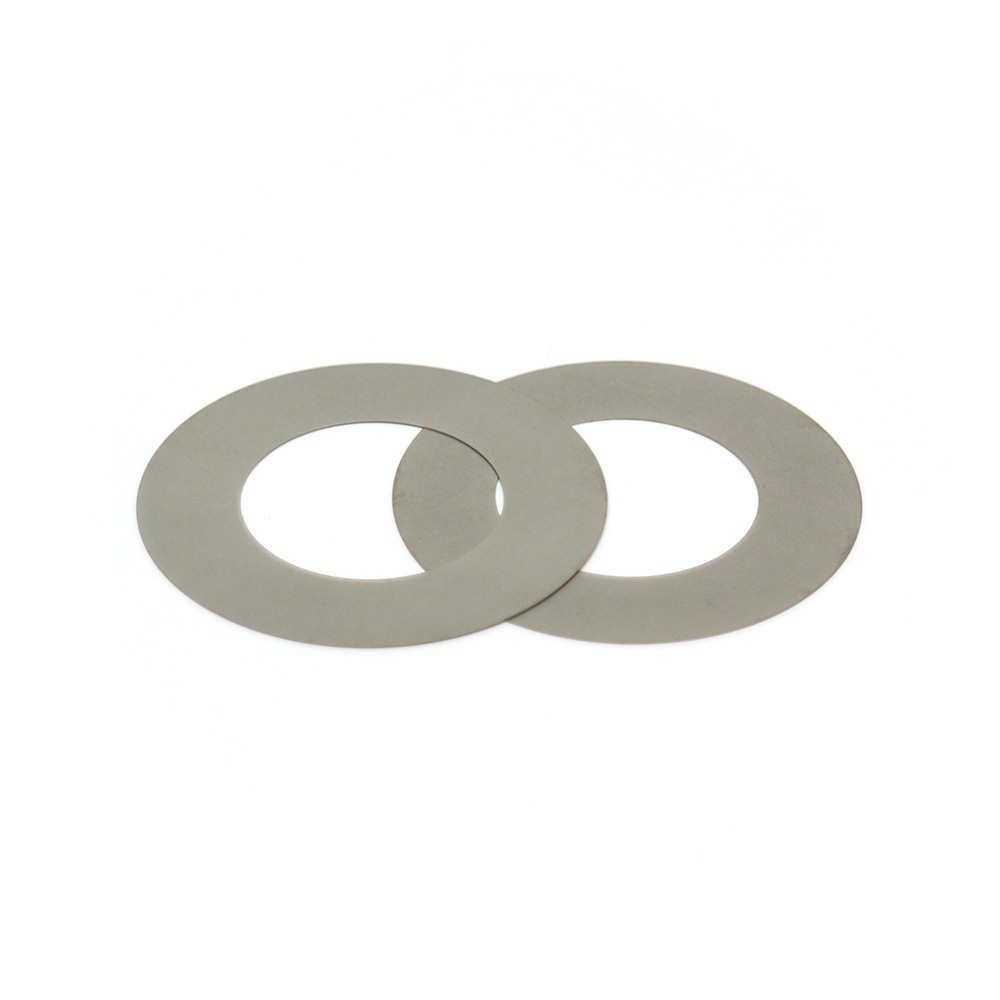

金刚石的尺寸需要考虑到表面粗糙度时,能够咬入接头材料。也就是说,金刚石需要比表面凹凸点之间的空隙更大。因此,表面越粗糙,通常所需的金刚石颗粒就越大。接触压力通常需要至少达到50 MPa,金刚石才能切入表面。由于表面压力限制,金刚石摩擦垫片往往需要覆盖整个接头界面,下图二展示了这样一片垫片。

最近,一款新产品进入了摩擦垫片市场。TRD Surfaces公司的MicroLock磁盘,通过激光在垫片表面产生撞击坑形成了微观凹凸点,密度约为每平方毫米180个。

其表面拓扑结构受到严格控制,因此可以为特定应用定制垫片。凸起的尖锐度和深度可以调整,以适应不同的表面压力和材料。据称,由于受控的表面拓扑结构,可以实现更高且更一致的静摩擦系数,即介于0.9至1.1之间,这优于其他方法。由于该方法也能承受较高的表面压力,垫片可以制成垫圈形式,覆盖螺栓拧紧时形成的压力锥面。

显然,使用摩擦垫片会增加组件的成本,然而,它们在减小承受剪切载荷应用所需的螺栓尺寸/强度,或解决使用中问题方面可能极为有用。添加摩擦垫片会增加接头内的表面数量,这与所使用的表面拓扑结构一起会增加嵌入量。由此带来的摩擦值增加以及防止滑动所需夹紧力大小的降低,通常足以弥补这种损失。

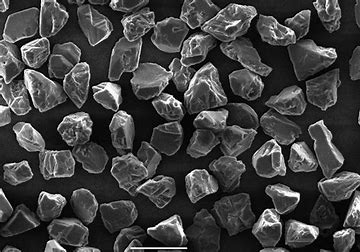

另一种增加界面摩擦的方法是通过沉积涂层和热喷涂涂层。可以在零件上沉积一层硬质陶瓷涂层以增加静摩擦系数。有几种方法可以实现,例如,在常温下,可以高速(由气体携带)将颗粒轰击到材料表面,形成一层薄的致密氧化铝膜或其他硬质陶瓷膜。这种工艺可以应用于安装在接头界面之间的垫片上,从而大幅增加界面摩擦力。

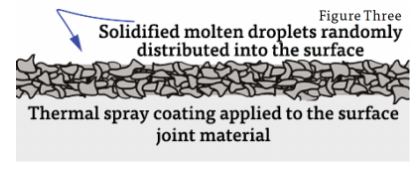

更常见的方法是热喷涂涂层,这涉及将熔融或半熔融材料喷涂到表面,形成一层改善摩擦和耐磨性的涂层(图三)。该过程类似于喷漆,但喷出的是熔融金属液滴。金属或陶瓷材料被加热后,使用电弧或高速气体射流将其喷涂到经过喷砂和清洁的金属表面上。熔融材料在撞击时被压平,形成致密、坚硬的涂层。熔融液滴随机地相互覆盖并粘附在清洁的金属表面上。涂层厚度约为0.1毫米至0.3毫米。

可以调整涂层以获得特定性能,例如增加粗糙度或硬度。这种方法的一个优点是,它是一种经济有效的方式来提高静摩擦系数,通常可实现高于0.5的值。

对于特定的应用,需要进行测试来确定能达到多大的摩擦系数。根据我们在机械工程应用方面的经验,使用摩擦垫片作为增加摩擦力的方式比使用喷涂涂层更为常见。

In the January - February issue of Fastener + Fixing Magazine, Dr Bill Eccles of Bolt Science Ltd discussed the importance of the value of interface friction in friction grip joints. In this follow up article, he highlights how having a proven approach to increase interface friction is very useful, with it being a way of resolving a service problem or minimising the bolt size needed in a shear loaded application.

Some proven approaches of this include the use of diamond impregnated friction shims, using friction shims with an engineered surface, or using a thermal spray coating on the plate surfaces. An advantage of increasing the coefficient of static friction in shear loaded joints is that they can allow a larger design margin to be achieved, or alternatively, allow the use of smaller bolts.

The use of friction shims in friction grip joints

Friction shims, also known as anti-slip shims, are thin metal or composite materials inserted between two surfaces in a joint to increase friction and improve grip. They increase the coefficient of static friction between the two surfaces that they are placed between, reducing the tendency of the surfaces to slide over each other under load.

Friction shims increase the friction between the surfaces usually through a combination of surface roughness and material properties. Typically, friction shims are made from materials such as stainless steel, titanium, or specially coated composites. The surface of the shim is often textured or coated with a friction enhancing material, to maximise grip.

When a load is applied to the joint, the friction shim provides additional resistance to joint slip when a shear load is applied. Fatigue and bolt loosening issues have been resolved by the placement of a friction shim in the joint. Bolt bending fatigue failures frequently being the result of joint slip as is self-loosening.

Diamond coated shims are available from a number of suppliers, most notably 3M and ATELA. These shims consist of a thin steel sheet with an electroless nickel coating having microscopic diamonds embedded – the size of the diamonds are such that they are not visible to the naked eye. The shim is placed on the joint interface on the shear plane so that the diamonds bite into both surfaces when the clamp force from tightening the bolts is applied, as illustrated in Figure One above.

In a press release in September 2024, 3M announced that it had sold more than 300 million friction shims worldwide. The coefficient of static friction provided by such shims depends upon the diamond grain size; the contact pressure; and the material pairing involved. Based upon information on the 3M website, the coefficient of static friction when such shims is typically of the order of 0.7, but varies depending upon the material, diamond grain size and surface roughness.

The size of the diamonds needs to be such that they will bite into the joint material when the surface roughness is considered. That is, the diamonds being larger than the gaps between the surface asperities. Hence, the rougher the surface, generally the larger the diamond grains need to be. The contact pressure typically needs to be a minimum of 50 MPa so that the diamonds will dig into the surface. Due to surface pressure limitations, diamond friction shims tend to cover the complete joint interface, such a shim is illustrated in Figure Two below.

Recently a new product has entered the friction shim market. MicroLock disks, from TRD Surfaces, have microscopic asperities created by the impact craters from a laser producing holes in the shim surface, in the order of 180 per square mm.

Recently a new product has entered the friction shim market. MicroLock disks, from TRD Surfaces, have microscopic asperities created by the impact craters from a laser producing holes in the shim surface, in the order of 180 per square mm.

The surface topology is tightly controlled so that the shim can be engineered for specific applications. The spike sharpness and depth can be adjusted to cater for different surface pressures and materials. Because of the controlled surface topology, a higher and more consistent coefficient of static friction is claimed. That is, values between 0.9 to 1.1, which is an improvement on other approaches. Since the method can also sustain high surface pressures, the shim can be in the form of washers covering the pressure cone formed when the bolt is tightened.

Obviously, use of a friction shim adds cost to an assembly, however they can be extremely useful in reducing the bolt size/strength needed in a shear loaded application, or in resolving a service problem. The addition of a friction shim will increase the number of surfaces within a joint, this together with the surface topology used will increase the amount of embedding. The increase in the friction value and the drop in the magnitude of the clamp force needed to prevent slip that this allows, usually more than compensates for such loss.

Another way to increase interface friction is through both deposited and thermal spray coatings. A hard ceramic coating can be deposited onto a part that increases the coefficient of static friction. There are a few ways in which this can be completed such as, at ambient temperature, particles at high-speed – carried in a gas – can be bombarded onto a material surface to form a thin dense film of aluminium oxide, or other hard ceramic. Such a process can be applied to a shim that is fitted between the joint interface that substantially increases the interface friction.

A more common way is by thermal spray coating, which involves spraying molten or semi-molten materials onto a surface to create a coating that improves friction and wear resistance (Figure Three). The process is analogous to spray painting, but the spray is droplets of molten metal. Metal or ceramic material are heated and then sprayed onto the grit blasted and cleaned metal surface using an electric arc or a high velocity jet of gas. The molten material is flattened on impact with a dense, hard coating being created. The molten droplets randomly form over each other and bind to the cleaned metal surface. The coating thickness being of the order of 0.1mm to 0.3mm.

The coating can be adjusted to have specific properties, such as increased roughness or hardness. One of the advantages of this method is that it is a cost-effective way to increase the coefficient of static friction typically achieving a value usually above 0.5mm.

For a specific application, a test is needed to determine what value of friction is being achieved. From our experience in mechanical engineering applications, the use of friction shims is more common than spray coating as a way to increase friction.

请先 登录后发表评论 ~